Scaffolding Training: Why It's Necessary for Your Workforce

Opening Vertical Prospective With Scaffold Towers =================================================

Take full advantage of the total potential of your tasks with scaffold towers. Increase performance and task effectiveness while making certain safety with steady systems and safety features. Different materials like aluminum, steel, and fiberglass deal with diverse job demands. Highlight correct setting up, maintenance, and compliance to guidelines for best efficiency. Discover the wide applications of scaffold towers in building and construction, event management, storage facility operations, and movie production. Beginning checking out vertical possibilities for your tasks currently.

Advantages of Scaffold Towers

Scaffold towers supply a multitude of benefits and advantages for different construction and maintenance tasks. One of the vital advantages of scaffold towers is the enhanced productivity they bring to worksites. By offering a secure and secure platform for employees to perform their tasks efficiently at different elevations, scaffold towers aid streamline operations and reduce downtime. This increased performance ultimately results in set you back savings and quicker job completion.

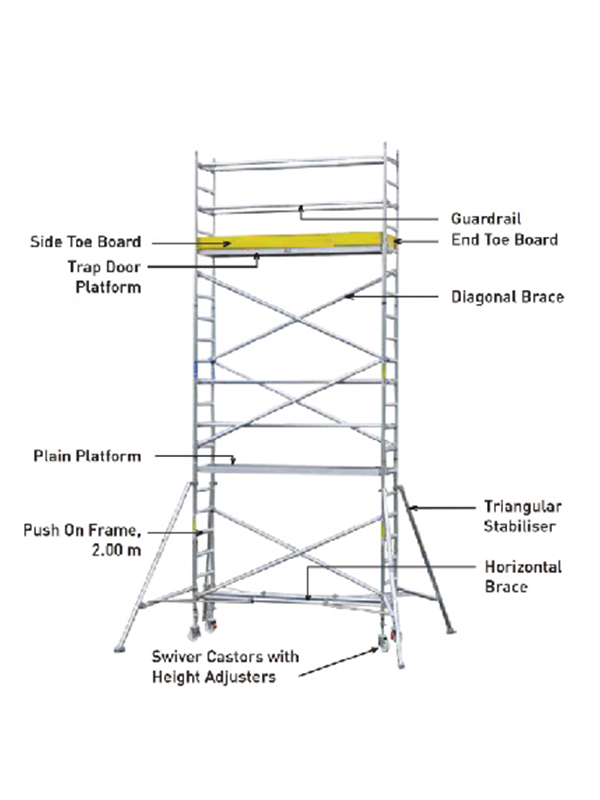

Additionally, scaffold towers add notably to boosted security on worksites. With functions such as guardrails, toe boards, and non-slip platforms, scaffold towers provide a safe and secure environment for workers to perform their tasks at raised degrees. This concentrate on security not only protects workers from crashes and injuries yet likewise guarantees compliance with health and safety guidelines.

Kinds Of Scaffold Towers

Various sorts of scaffold towers are commonly utilized in building and upkeep jobs to supply safe and secure elevated systems for workers. Scaffold towers are readily available in various products such as light weight aluminum, steel, or fiberglass, each offering distinct advantages based upon the specific requirements of the project. Aluminum towers are light-weight and corrosion-resistant, making them excellent for jobs calling for frequent movement, while steel towers are robust and durable, ideal for heavy-duty applications. Fiberglass towers are non-conductive, making them secure for electric workplace. https://nottinghillscaffolding.co.uk

Elevation variants are another essential aspect to take into consideration when selecting a scaffold tower. Towers come in numerous elevations, varying from small mobile towers for low-level tasks to large, fixed towers that can reach considerable elevations for tall structures. The height of the tower ought to be picked based upon the details needs of the task, ensuring that workers have risk-free access to elevated workplace. Recognizing the different types of scaffold towers available permits project supervisors to pick one of the most suitable option for their building and construction or maintenance jobs.

Safety And Security Features to Try To Find

When taking into consideration scaffold towers for building and construction or maintenance jobs, one of the crucial facets to review is the presence of necessary safety functions. Fall defense is critical in making certain the well-being of workers at elevated elevations. Try to find scaffold towers outfitted with guardrails, harness accessory factors, and toe boards to stop falls.

In addition, security measures are critical to avoid the threat of the tower tipping over. Attributes such as flexible legs for leveling on uneven surfaces, outriggers for improved base assistance, and securing systems for protecting the tower in place are crucial for making sure security throughout use.

To ensure a risk-free workplace, it is important to invest in scaffold towers that focus on both autumn protection and stability. Prioritize designs that comply with security regulations and standards to reduce potential dangers. By choosing scaffold towers with durable safety and security functions, you can improve worker security and efficiency on building and construction and upkeep projects.

Proper Assembly and Usage Tips

To assure the safe and reliable use of scaffold towers, thorough attention to appropriate setting up and usage standards is vital. When setting up scaffold towers, it is essential to follow the supplier's directions diligently. Begin by verifying that all parts are in excellent problem and compatible prior to starting assembly. Constantly make use of the suitable individual safety devices, such as safety helmets and handwear covers, during assembly to prevent any possible accidents. In addition, make certain the scaffold is set up on a stable and level surface area to prevent any type of instability concerns during use.

Safety and security safety measures ought to be strictly complied with when working on scaffold towers. Always safeguard the tower to prevent any type of activity or tipping. Routinely examine the scaffold for any signs of wear or damage, and ensure that it is not strained past its capacity. Put up guardrails and toe boards to avoid falls and guarantee that all accessibility factors are secure. Lastly, never ever compromise on security if unsure, look for expert suggestions or training prior to utilizing the scaffold tower.

Maintenance and Examination Standards

To assure the security and integrity of scaffold towers, it is necessary to stick to safety and security examination treatments, conduct regular upkeep checks, and abide by appropriate laws.

Safety inspection procedures aid recognize prospective dangers, while regular upkeep checks make sure that the scaffold towers are in peak working problem.

Conformity with regulations is important to ensure that the scaffold towers fulfill industry standards for secure use.

Safety And Security Examination Procedures

Appropriate maintenance and inspection standards are vital for making sure the security of scaffold towers in upright construction projects. Conducting a safety audit prior to each usage is essential to recognize any kind of prospective hazards or concerns that may compromise the stability of the structure.

An examination checklist should be adhered to diligently to evaluate the condition of parts such as frameworks, dental braces, systems, and guardrails. This list ought to consist of verifying proper installment, checking for any indications of damage or wear, making certain stability on the ground surface area, and confirming that all security mechanisms remain in location and functioning appropriately.

Regular Maintenance Checks

Doing normal maintenance checks according to established guidelines is crucial for supporting the structural stability and safety of scaffold towers in upright building jobs. These preventative measures not only ensure the stability of the framework however likewise add to tools longevity.

Routine maintenance checks ought to include examining all elements for damage, checking for loosened links, validating the stability of the base plates, and taking a look at the total condition of the scaffold towers. By adhering to a rigorous upkeep timetable, possible issues can be recognized and rectified promptly, minimizing the risk of mishaps and making certain peak efficiency.

Prioritizing upkeep not just enhances safety and security on-site but additionally prolongs the life-span of scaffold towers, eventually maximizing their worth and performance in vertical building jobs.

Compliance With Regulations

Adhering to established upkeep and inspection standards is crucial for guaranteeing conformity with regulations relating to scaffold towers in upright building and construction jobs. Regulatory needs mandate that scaffold towers satisfy particular safety standards to protect employees and the public. Routine maintenance checks play an essential role in promoting these criteria.

Examinations must be performed by certified personnel to identify any prospective threats or structural weaknesses that might endanger the stability of the scaffold tower. By following rigid upkeep and examination protocols, building and construction companies can show their commitment to safety and regulatory compliance. Failure to follow these guidelines not just places individuals in danger however also reveals organizations to possible legal implications.

Therefore, strict adherence to maintenance and inspection guidelines is non-negotiable in the building sector.

Applications in Numerous Industries

With the increasing demand for functional and secure raised working solutions, scaffold towers have found extensive applications throughout numerous markets. These adaptable frameworks offer a variety of benefits, making them crucial in various work environments.

Below are 4 essential industry applications where scaffold towers play an essential role:

Building Industry: Scaffold towers are extensively made use of in building for tasks such as paint, gluing, and electric operate at elevations. Their portability and adjustability make them optimal for maneuvering various task sites.

Event Administration: In case market, scaffold towers are used for setting up lighting, sound tools, and decorations for performances, festivals, and various other big gatherings. Their security and elevation make them crucial for producing impactful occasion experiences.

Storehouse Workflow: Warehouses often use scaffold towers for accessing high shelves, conducting stock checks, and doing upkeep tasks. Their convenience makes it possible for storehouse personnel to function effectively and securely at raised elevations.

Movie and Television Manufacturing: Scaffold towers are important in the entertainment industry for lights arrangements, video camera procedures, and set building and construction. They give a steady system for developing enthralling aesthetic experiences on screen.

Frequently Asked Concerns

Can Scaffold Towers Be Made Use Of for Residential Projects, or Are They Mainly for Industrial Use?

Scaffold towers provide residential adaptability along with commercial applications. When utilized in property projects, safety preventative measures need to be purely abided by. Proper training, evaluation, and adherence to guidelines are necessary for risk-free and reliable usage.

Exist Any Kind Of Details Weight Restrictions or Tons Abilities for Scaffold Towers? https://nottinghillscaffolding.co.uk/index.html

When thinking about scaffold towers, it is important to stick to safety and security policies by comprehending the maximum capability and lots limitations. These specs differ based on the tower's layout and function, ensuring secure use in various settings.

For how long Does It Normally Require To Set Up a Scaffold Tower?

The assembly time for a scaffold tower can vary depending upon dimension and intricacy but normally varies from 1-4 hours. To assure assembly performance and safety and security, follow maker instructions, utilize appropriate devices, and adhere to all safety precautions.

Can Scaffold Towers Be Used on Irregular or Sloped Surface Areas?

When pondering the usage of scaffold towers on irregular or sloped surfaces, security issues are paramount. Safety preventative measures must be carefully followed to guarantee the scaffold is strongly positioned and that risks of accidents or collapses are reduced.

Exist Any Rules or Certifications Required for Making Use Of Scaffold Towers in Particular Industries?

Security demands and market standards mandate correct training programs and accreditation procedures for making use of scaffold towers in numerous sectors. Complying with these guidelines assures a secure working environment and reduces threats connected with operating at elevations.

Verdict

To sum up, scaffold towers use countless advantages in numerous industries as a result of their upright capacity.

It is crucial to take into consideration the various types of scaffold towers available and focus on safety and security functions when choosing one for usage.

Proper setting up, use, maintenance, and evaluation standards must be followed to assure the safety and performance of scaffold towers.

On the whole, scaffold towers are a valuable tool for accessing elevations and completing jobs successfully and firmly.